More than 30 years ago, a pair of young scientists landed in Tucson and helped develop electronically dimmed glass that would later find its way into millions of cars as auto-dimming rearview mirrors.

Now they’re looking to push the latest version of their technology into millions of homes, as spiraling energy costs are driving demand for energy-efficient windows.

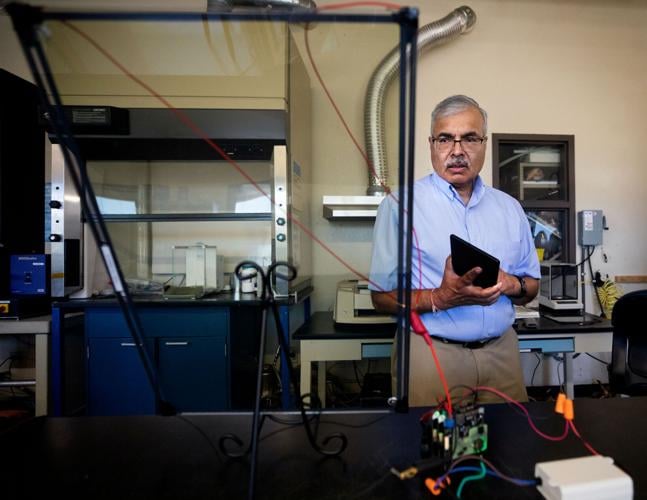

Tucson-based startup Glass Dyenamics, co-founded by material scientists Anoop Agrawal and John Cronin, is raising funds to set up a pilot manufacturing line for its dimmable glass windows, after recently hitting a major milestone in a testing program with the U.S. Department of Energy.

The company has developed its own patented electrochromic glass — which is dimmed by means of a low-voltage electrical current acting on layers of special materials — with the aim of cheaply producing it for residential windows.

While electrochromic glass technology has been around for decades, its use for windows has been limited to commercial buildings because of its high cost — some 10 times the cost of standard insulated windows.

Christopher Angelo, a former solar materials company executive who joined Agrawal and Cronin to co-found Glass Dyenamics in 2017, said the company’s technology can help homeowners achieve energy savings of up to 20% — paying for itself faster than rooftop solar panels.

“We believe that this technology can achieve a much greater percentage of mass adoption than residential solar,” Angelo said.

Pioneering work

Agrawal and Cronin worked to develop electrochromic glass for self-dimming auto mirrors and windows in the late 1980s and 1990s at Donnelly Corp., which made mirror components and had its advanced technology center in Tucson.

Agrawal got his doctorate in materials science and engineering from MIT, where Cronin also completed post-doctorate studies in material science.

Michigan-based Donnelly became a leading supplier of self-dimming auto mirrors, and it was acquired by auto parts supplier Magna International in 2002.

In 2004, Agrawal and Cronin founded a consulting firm, AJJER LLC, and tech startup Berylliant Inc. based on technology to detect particles of beryllium, a toxic metal used in industrial processes. That company is still based in Tucson and is profitable, Cronin said.

The pair continued to work on electrochromic glass, and later formed a company in Tucson called Polyceed with Maha Achour, a MIT physics Ph.D based in California, to advance the technology.

Angelo later joined the company and the name of the company was changed to Glass Dyenamics to reflect its new technology.

“We were working on a variety of different technologies,” Agrawal said, besides electrochromic glass including a collaboration on beryllium analysis with Los Alamos National Laboratory and anti-microbial materials.

The company ended up leasing Donnelly’s former Advanced Technology Center on East Fort Lowell Road and set up labs there to develop its glass products.

Early on, Glass Dyenamics got a $1.5 million grant to advance its research through the Wells Fargo IN2 business incubator, in partnership with the DOE’s National Renewable Energy Lab, which funded successful high-stress weatherization testing of the company’s glass.

How it works

Like existing electrochromic technologies, Glass Dyenamics glass uses a low-voltage electrical current to activate chemical layers that darken.

Agrawal likened the design to a dry-cell battery, including a solid electrolyte, or layer that allows electrons to flow between electrodes to charge or discharge a battery.

But instead of exchanging electrons for energy storage, the current changes the state of the active layers in the glass.

“When we charge it, it’s one color, when it’s discharged it’s another color,” Agrawal said.

While electrochromic glass is commonly made with layers of metal oxides, Glass Dyenamics uses proprietary, organic dyes to achieve the dimming effect. The company has 15 issued patents and another 10 applications under review, Agrawal said.

The company’s glass panes start dimming almost immediately and reach their full dimming, down to as low as 1% light transmission, within a couple of minutes.

Agrawal said the company has proven the scalability of its technology to window sizes of meter wide and larger.

In a lab demonstration, he and Cronin showed showed a meter-wide strip of glass dimming in about a minute.

"Scalability is important as many such devices suffer from (poor) scalability, which we had to overcome systematically by material modifications," Agrawal said.

While Glass Dyenamics has shown its technology works, now it is working to show it will last.

Testing milestone

In May, Glass Dyenamics announced that its dimmable glass lasted an industry-leading 150,000 cycles over 5,000 hours under standard durability testing conditions, while also performing within rarely-achieved optical performance degradation industry standards.

Achieved in collaboration with the National Renewable Energy Laboratory (NREL) in Golden, Colorado, the test results far exceed the minimum 50,000 cycle threshold required by ASTM International, formerly known as American Society for Testing and Materials.

Cronin said the company has refuted the idea that organic dyes can’t match the durability of dimmable glass made with inorganic metal oxides.

“We’ve proven that it’s extremely durable,” said Cronin who is originally from Dublin, Ireland, and after getting his Ph.D. from Trinity College and attending MIT came to Tucson in the 1980s to work as a research fellow at the University of Arizona.

Only three companies in the world have ever achieved the minimum 50,000-cycle standard, the company says.

Glass Dyenamics’ collaboration with NREL also has led to the development of customizable glass-tint colors with privacy benefits, the company said.

Robert Tenent, senior materials scientist at NREL, noted the government lab has been working on organic dye based electrochromics with Glass Dyenamics since the initial collaboration with the Wells Fargo’s incubator and continue to be impressed.

“We believe that these results open the door to a new paradigm of dynamic glazing functionality and customer affordability,” Tenent said in remarks when the test results were announced.

Angelo, who spent seven years as chief financial officer at a San Francisco company that makes silicon material for solar panels, said lower expected production costs will make the company’s glass a viable alternative to rooftop solar installations as a way for homeowners to cut their power bills while helping the environment.

“The primary value proposition of residential solar is reducing your monthly energy bill and our view is, look, for homes with with our technology, we can provide that same customer value proposition for more than 10 (times) less cost,” he said, adding that also avoids dependence on a local utility’s power grid.

Looking ahead, the company is working to raise an initial round of venture-capital funding to build a pilot glass plant in Tucson, said Angelo, who recently moved from the San Francisco Bay area to Bend, Oregon.

Raising money

The company is initially focusing on small panes used for doors and home entry areas, but has demonstrated the technology can work in meter-wide glass window panes and expects to produce panes in the one- to two-meter size, or from about three to 6.5 feet.

The company so far has raised about $4.5 million in capital, mainly from friends and family with about $1 million from outside investors, Angelo said, noting that the other companies that reached the 5,000-hour durability standard collectively raised $80 million.

“One of the key reasons for that is the founding team that we have are well-renowned, respected scientists in this particular technology,” he said. “And of course, they were instrumental in developing and bringing to market the most successful electrochromic technology today, which is the automobile rear-view mirror.”

Check out some innovative and sometimes overlooked energy-saving strategies that can help you and your wallet survive Tucson's summer swelter.