A Tucson-based startup is one of two finalists in an international competition to push development of new technologies to reuse mine tailings — leftover material from mining operations.

Auxilium Technology Group, founded by entrepreneur and chemist Abraham Jalbout and three University of Arizona faculty members, won a $300,000 award to build a demonstration plant to produce an insulated foam product from mine tailings as part of a technology challenge sponsored by Australian mining giant BHP.

Last year, Auxilium was among 10 companies and academic research groups picked to move on to the laboratory stage of the BHP Tailings Challenge, from an initial field of 154 applicants from 19 countries.

On April 20, BHP held a “demo day” event at which the company was expected to pick three winners to move forward with prototype processing plants.

Instead, BHP chose two — Tucson’s Auxilium and Americas Tailings Inc., a Colorado-based company that has developed a system to turn mine tailings into fertilizer products.

One or both of the finalists will be in line for a final challenge prize of $8.6 million to implement an on-site industrial pilot plant, with the goal of entering into a commercial agreement with a third party that will use its tailings as raw material to produce marketable products.

For the next stage, Auxilium is finalizing plans to build a pilot tailings processing plant for the challenge at the UA-owned San Xavier Underground Mining Laboratory west of Sahuarita, Jalbout said.

Jalbout said he was confident his team had a winning technology but faced other, well-funded challengers including some international academic and business consortia.

“I think we’re all confident about the work we’re doing, and I think what really helped was having a strong business case, as well as the technical case,” he said.

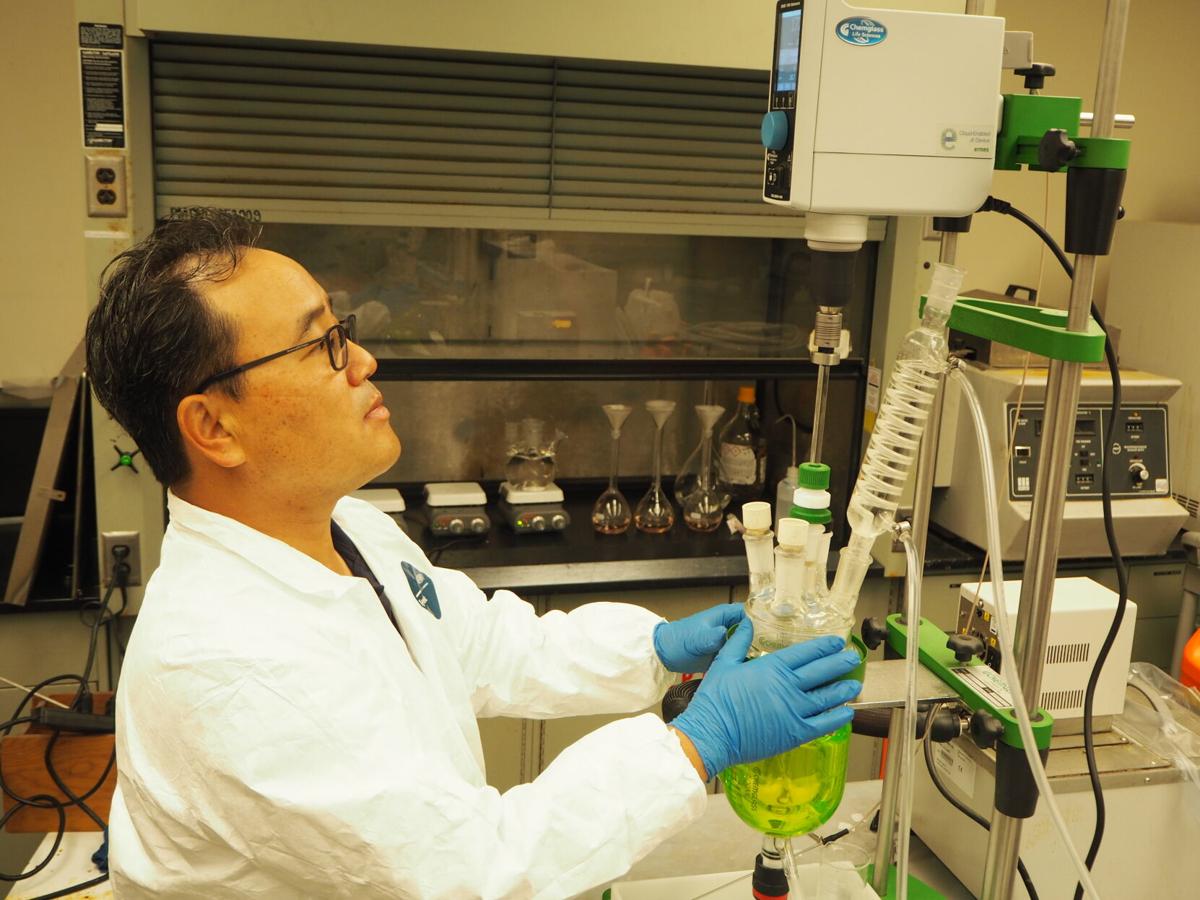

Jalbout launched Auxilium in 2020 with three UA faculty members who developed the tailings tech: associate professor Moe Momayez, interim head of the Department of Mining and Geological Engineering; Jaeheon Lee, an associate professor of mining and geological engineering; and Dominic Gervasio, associate professor of chemical and environmental engineering.

The company licensed from the UA three mining inventions by the UA co-founders — a highly efficient leaching process that replaces highly toxic cyanide used to extract gold from ore; a system of floating panels to cover tailings ponds and save water; and a spray-on thermal insulating material made with mine tailings.

Jalbout said mining companies like BHP are eager to find solutions to the problem of mounting tailings, which are costly to store and are regulated under environmental laws because they contain hazardous heavy metals that can pollute the air and water.

Phoenix-based miner Freeport McMoRan, which has been fined for air-quality violations prompted by tailings dust blowing from its Sierrita Mine near Green Valley, sponsored Auxilium’s entry into the UA’s tech incubator, the UA Center for Innovation, in 2020.

Jalbout said the pilot plant at San Xavier will be able to process a ton of tailings per day, compared with about 20 kilograms or about 44 pounds of material used in the lab demo.

With its processes, Auxilium can extract valuable industrial chemicals such as sulfuric acid and ferric sulfate from tailings, along with remaining metals of value, such as copper, molybdenum and gold, using its high-efficiency extraction process invented by Lee, Jalbout said.

After removing water from the tailings, the final process invented by Momayez is used to turn the stripped tailings into an insulating “geofoam” that can be sprayed on or applied in sheets to block heat from rock walls from working areas in underground mines.

Besides saving money on mine cooling, the material could be used in the construction industry, Jalbout said.

Looking ahead, if it wins the challenge, Auxilium may work with BHP to install its tailings-processing plants at the company’s mines, which include large copper-mining operations in Chile and coal, nickel and iron ore mines in Australia.

BHP also is partnered with Rio Tinto Group to develop the controversial Resolution copper mine near Superior, Arizona.

Jalbout said going forward, Auxilium could partner with mining companies to build its processing plants at mining sites, or with companies that already process mine waste.

The company already has been working with Metso:Outotec, a major supplier of mining and industrial equipment based in Helsinki, Finland, to prove its concept for the BHP Tailings Challenge, he said.