Dennis O’Brien and William Tweed located the Christmas Mine about 1880 and sold their claims to Phelps Dodge shortly thereafter. Yet the mine could not be exploited until the land was removed from the San Carlos Indian Reservation boundaries in 1902.

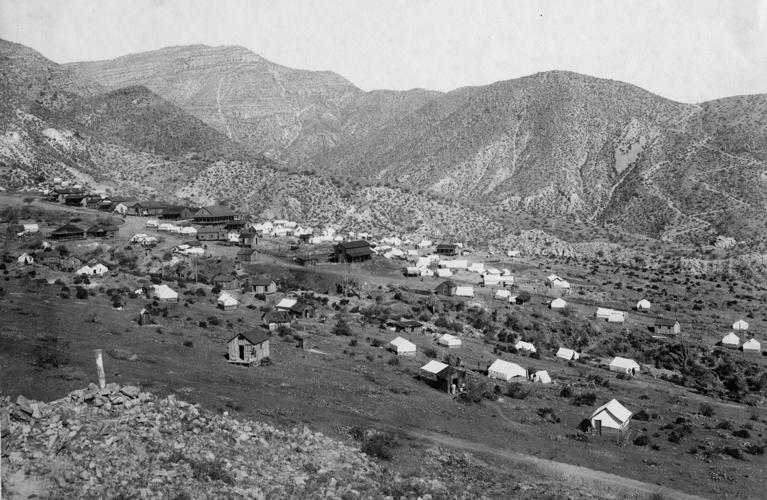

Claims staked Christmas Day that year by G.B. Chittenden and N.H. Mellor gave the mine and subsequent town its name. The town’s population reached 1,000 by 1932 and its post office (1905-1935) was highly sought after for its “Christmas” postmark by people sending letters or postcards over the holiday season.

The mine, located on the eastern slope of the Dripping Springs Mountain Range, about eight miles north of Winkelman in the southwestern corner of Gila County along Arizona 77.

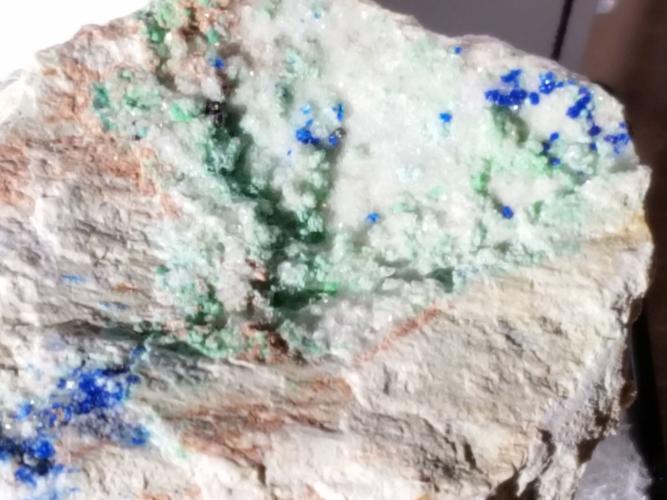

Mineral deposits were found in Naco limestone with a capping of andesite on the surface. The Christmas ore body in the Banner Mining District proved challenging to mine because of its irregular and faulting contours. Ground support also proved challenging necessitating the prompt filling of mined areas.

Abundant ore minerals include chalcopyrite, bornite, chalcocite, covellite and cuprite mixed with gangue rocks garnet, magnetite and quartz.

A dispute between Phelps Dodge and the Saddle Mountain Mining Co. in the early 1900s was settled in court with the latter retaining the property and erecting a small smelter.

Production began in 1905 with a succession of mining companies intermittently operating the property throughout most of the 20th century.

A 7,300-foot-long wire rope Bleichart aerial tramway was built on the property in 1916, with a carrying capacity of fifty tons per hour. It ran from a 250 ton ore bin at the No.3 shaft to a 1,000 ton ore bin nearby the Arizona Eastern Railroad connection, an elevation gradient of 950 feet.

The rail transported the ore for processing at the Hayden smelter near Winkelman.

Surface hauling involved the use of a one-ton Ford truck and a two-ton Nash Quad truck.

The mine received electricity from the San Carlos Irrigation Project via a 66,000-volt transmission line nearby the main shaft.

The mine was known for the production of high lime fluxing ore sold by the Sam Knight Mining Lease Inc., which leased the property in 1939. Its primary customer was the Hayden smelter that used the product to treat the copper concentrate received from the nearby Ray Mine.

By 1942, ore from the Christmas Mine averaged a percentage slightly above 2 percent copper and around 30 percent lime. Gold and silver averaged 0.005 ounces per ton and 0.23 ounces per ton, respectively.

The McDonald shaft reached a depth of 1,780 feet, with several drifts running in excess of 1,200 to 2,400 feet. The surface structures included a compressor building, hoist, change house, office and warehouse. Ore was hauled by electric locomotive from the haulage tunnel 400 level 2000 feet to the flotation mill built by the Southwestern Engineering Co. in 1929 on the surface near the (main) No.3 shaft.

In 1962, the mine employed 142 men, working three shifts and producing 600 to 800 tons of ore per day. The stopes were 18 feet high by 18 feet wide on the 1,400-foot level worked by miners using Ingersol-Rand drills.

Underground water continued to be a problem necessitating the use of three Hazleton pumps to pump 2,500 gallons per minute.

Open-pit mining operations were carried out by front-end loaders beginning in 1966. Floatation was applied to both sulfide and oxides ores with 90 percent recovery on sulfides and 50 percent recovery on oxidized material.

The John Mediz rock shop in Globe secured a contract with the Inspiration Consolidated Copper Co. (then the property owner) enabling it to collect mineral specimens including apophyllite, dioptase, kinoite and silver from the property in 1980. Declining copper prices forced the mine to close in the early 1980s. It is estimated that 480 million pounds of copper ore were mined on the property, most notably during open-pit mining operations.

Analysis undertaken of the property in 1987 by John Kuhn, a consulting geologist, revealed a good stockpile of oxide copper ore around 100 million tons averaging 0.47 copper per ton. Kuhn also reported on the potential of processing the surrounding pyrite for the purpose of manufacturing sulfuric acid.

The property is currently owned by Freeport-McMoRan, which is researching the size and scope of the Christmas copper ore body.