Arizona was rated one of the top five producers of architectural marble in the early 20th century.

Located near Fort Bowie in MacIntosh Canyon — sometimes known as Marble Canyon — a marble mining operation was established in 1909 after positive exploration undertaken by the Arizona Geological Survey the previous year.

John G. Kerr, a representative for the Arizona Marble Company based in Colorado, deemed the property an important asset with rich marble deposits.

He considered it worthy of an investment including the establishment of an access road from the quarry site to the railroad, 14 miles north to Bowie. This would allow for the accessibility of ore shipments. It would include the erection of bridges, a necessity when traversing the natural features of the rugged landscape such as the canyons and a massive gorge, the size of which called for the use of rail trestles emplaced with concrete and pine timbers.

The Arizona Marble Company owned 11 claims at this site, totaling 1,760 acres.

The company supplied high-grade marble to builders in cities throughout the United States.

Banks and churches were some of the buildings constructed using marble from this site in the northwestern part of the Chiricahua Mountains.

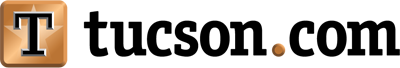

The marble blocks from this site measured more than 6 feet high and were highly sought after because of their colors, which included black-, blue-, green-, white- and rose-colored veins.

At 60 tons per load when placed in wagons, they were moved by 110 power-traction horsepower steam engines.

Marble is defined as a limestone or dolomite that has been naturally heated (metamorphosed) and recrystallized. Marble mining required a skill set to preserve the final product.

The miners were limited in their ability to use explosives for fear that it would damage the rock. They relied instead on the use of steam-powered drills, saws and derricks to cut, shape and hoist the material before it was transported out of the quarry.

The two derricks that operated at the site were rated for 30 and 50 tons. It was the job of two 115 horsepower water tube boilers to supply the necessary steam for operating the rock drills in the quarry.

The Arizona Marble Company relied on equipment provided by the Sullivan Machinery Company to aid in the marble-extraction operation.

Financed by a group of Denver investors, a steam-powered mill was developed at the site to aid in hoisting, sizing and cutting the slabs of marble. It also pumped water from four constructed wells and was fueled by native vegetation, including juniper and oak trees. As those sources diminished, coal imported from another site was used.

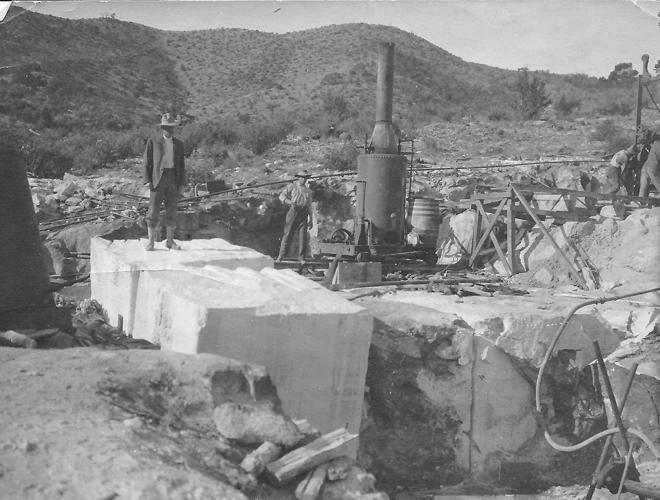

A machine shop and a blacksmith shop serviced the operation with the miners living in a tent camp several hundred feet away.

Today, all that remains of the original quarry operation are boilers, cables, heavy-duty wheels, milling equipment, concrete piers and wooden derricks, along with a water pump engraved Fairbanks Morse.

Visitors to the quarry site on private land are impressed with the massive size of the marble blocks. They attest to the skill and labor that went into the mining enterprise.