The Lakeshore copper deposit 32 miles south of Casa Grande in Pinal County, while showing enough promise to attract a succession of investors over more than a century, was also once the site of a $96 million loss for a mining company.

The porphyry type copper deposit encompasses multiple mining properties on 10,500 acres. It is located under pediment near the southwest base of the Slate Mountains, comprised of dominant schist-bearing rock.

Mineral outcrops in granite, limestone, quartzite and diabase composed of copper silicates and iron oxides were located on what became known as the Treasure State and Drake Claims.

Discovered by Trout and Atchison in the early 1880s, it was abandoned after several years of development including a 112-foot-deep shaft, due to a declining market in copper prices.

The predominant copper mineral is chrysocolla, a hydrous silicate occurring in fractures of schist intermixed with calcite and claylike material.

From 1917 to 1919, the mine was leased to Frank M. and Charles Leonard, who developed the ore body on three levels by sinking a 225-foot-deep vertical shaft.

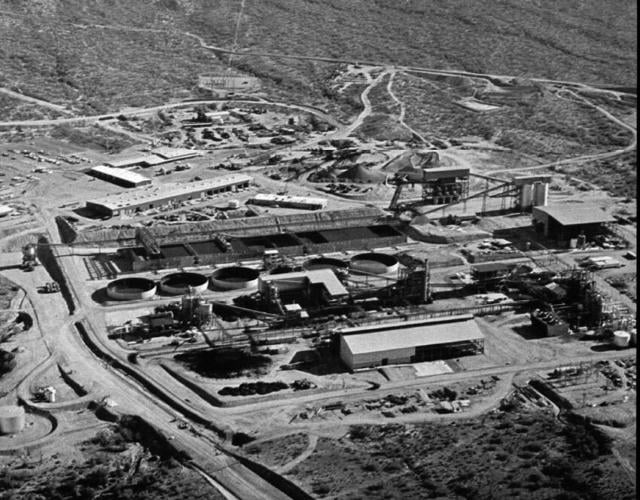

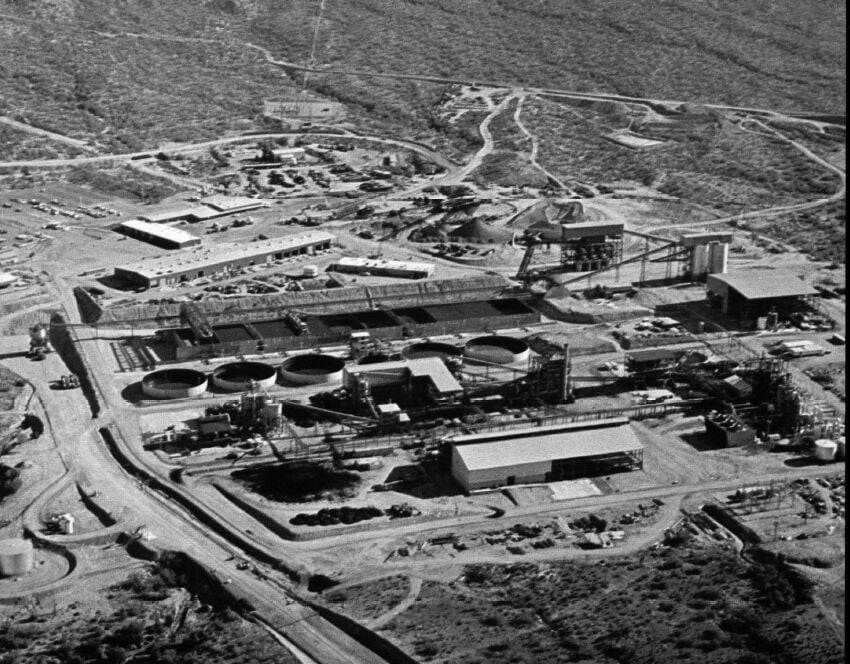

Aerial view of the surface facilities at the Lakeshore Mine circa 1971.

An estimated 280,000 pounds of copper was extracted by 1929 through surface excavations, churn drill holes and underground workings. The U.S. Bureau of Mines examined the property in the 1940s, producing a report in 1950.

In 1960, Transarizona Resources Inc. leased the property from the Bureau of Indian Affairs and went on to develop the mine as a small open pit known as the El Paso Pit. A plant was constructed to treat the oxide ores in limy metasediments.

Technical difficulties in plant functionality, along with challenges involving the ores not being economically amenable to customary leaching processes, forced Transarizona into receivership.

Several years later the El Paso Natural Gas Co. acquired an interest in the property, extracting an additional 350,000 tons of oxide ore from the pit by the end of the decade.

El Paso Natural Gas also initiated an induced polarization survey, resulting in the discovery of sulfide mineralization west of the El Paso Pit with an average assay value of 1.75% copper.

The Lakeshore ore body extended 6,000 feet long and 2,500 feet wide. Broken down into multiple zones from highest to lowest, these included a disseminated oxide zone with surface depths averaging 500 feet to more than 1,000 feet, disseminated sulfide zone (containing chalcopyrite, chalcocite and bornite) with an average thickness of 500 feet in andesite and porphyry rocks, and a tactite zone comprised of a tabular deposit of higher grade sulfide ore.

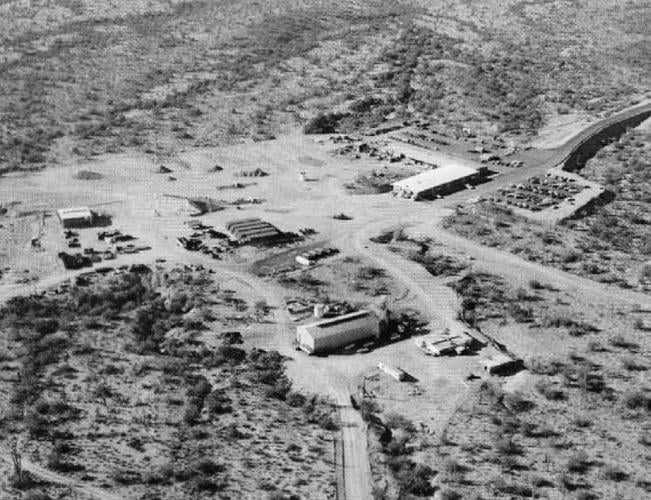

Preparations were undertaken to drive twin declines at the Lakeshore Mine circa 1969 beginning underground operations.

Development occurred as a joint venture between the Hecla Mining Co. and El Paso Natural Gas Co. Hecla, known for its mining ventures with the Lucky Friday and Star Morning silver mines in Coeur d Alene, Idaho, acquired a 50% interest in the Lakeshore property by offering one million shares of Hecla stock to develop, operate and finance the project in 1969.

Enticed by reports that Lakeshore contained 500 million tons of commercial ore averaging 0.75% copper and a 20-year mine life, Hecla became the primary operator of the 10,505 acres of land leased by the tribe then known as the Papago (now the O'odham).

Electricity was purchased from the Papago Tribal Utility Authority and supplied by the Arizona Public Service Co. Several wells were drilled on the property including one 1,000 feet deep to supply more than 3,000 gallons of water per minute.

Original development was expected to be open pit. However, separate higher grade copper oxide and copper sulfide ore bodies necessitated the preference of underground methods, including panel caving, which was more attractive due to less capital expenditure and greater financial return.

Workflow model depicting operations at the Lakeshore Mine.

Development commenced in 1969 with a roast-leach-electrowinning pilot plant and assay laboratory erected by 1971 along with two parallel 15-degree declines constructed, including one used to transport sulfide ore from an underground primary crusher on a 42-inch 7,200-foot belt conveyor to the surface. The other decline was used to transport workers and material into the mine with a hoist. Oxide ore was extracted at another site, using a hoist to surface through a 14-foot circular shaft.

Products from Lakeshore included copper cathodes and cement copper pellets transported by truck to the main line of the Southern Pacific Railroad in Casa Grande. The cathode copper was then shipped to fabricators including Southwire Co. in Carrollton, Georgia, while the cement copper was shipped by rail to ASARCO smelters in Hayden, Arizona; El Paso, Texas; and Tacoma, Washington.

Map denoting location of the Lakeshore Mine in Arizona.

A 250-ton per day Noranda DRI (Direct Reduced Iron) Plant was built in 1973, wherein iron produced was used to recover copper from acid solutions. This process, known as cementation, was used effectively at Lakeshore for two years until replaced by the solvent extraction/electrowinning process in the 1980s.

The mine had its share of casualties including two miners, David Deeder and Terry Udall, who operated a 40-ton front-end loader that capsized, bursting into flames, because of a cave-in. Three of their colleagues managed to escape.

Compressed air supplied to the miners helped fan the flames among the timbers. Trapped 1,200 feet below the surface in a vertical shaft with smoke and temperatures around 150 degrees from the fire for eight days in August 1973, both men succumbed to the environs.

Difficulties in keeping the ore passes open in the declines along with underground panel caving problems delayed full production until 1975. Challenges with the pelletization of the cement copper because of high moisture content were also factors.

Hecla’s actual production was brief, beginning in April 1976 until suspended in September 1977. A depressed copper market was coupled with the impact of high start-up and operational costs involving the mine and mill infrastructure, negatively impacting Hecla’s profit margin. As a result, 1,500 employees were laid off.

The Lakeshore Mine was Hecla’s worst investment, costing it $96 million.

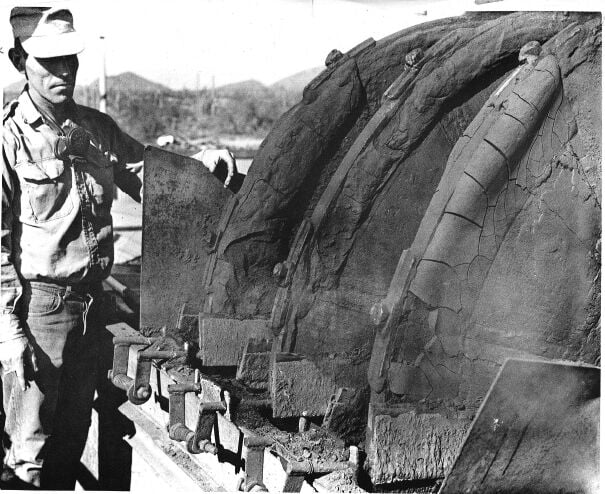

Iron oxide residue from the roasting and acid leaching of sulfide copper concentrates known as leach residue filter cake as seen at the Lakeshore Mine.

The mine reopened in 1981 under the management of Noranda Lakeshore Mines, a subsidiary of Noranda Mines Ltd. of Canada, which purchased the property including the plant from Hecla for $9.4 million cash in 1979.

Production renewed in 1981 from vat leaching of the oxide ore to produce more than 26 million pounds of cathode copper. A $7 million solvent extraction plant was used to enhance copper recovery. Negatively affected by economics, underground mining ended in 1983, having been replaced with in-situ leaching.

In 1988, Cyprus Tohono Corp. leased the Lakeshore property, then known as the Casa Grande Mine, so that it could obtain the onsite roaster as a worldwide shortage of smelting capacity existed at that time. The company conducted in-situ leaching operations in areas known as the Lunchroom and Tool Crypt.

Residual copper production within the heap leach pad and copper cathode production was initiated in 2005 as the result of the refurbishment of the SX/EW facility. These operations ended in 2008.

The mine is currently in the care and maintenance status of the Cyprus Tohono Corp., with no active mineral production.