Turning potentially hazardous power-plant waste into a better building material is the mission of Acrete, a University of Arizona technology startup.

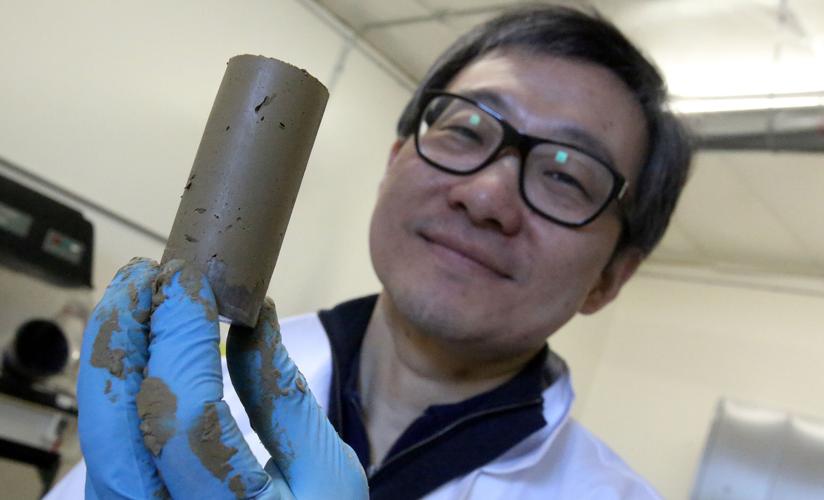

Co-founded by inventor Jinhong Zhang, a UA associate professor of mining and geological engineering, Acrete is based on a new formula to maximize the use of fly ash — a byproduct of coal-burning power generation — in concrete.

And going forward, the company hopes to develop applications to allow the use of other industrial byproducts, such as mine tailings, said Abraham Jalbout, an entrepreneur who joined with Zhang to launch Acrete.

Fly ash, which is captured from coal-plant exhaust gases, carries toxins including arsenic and heavy metals and can be hazardous if inhaled. Typically stored in ground basins or landfills, it can pose a risk of contaminating groundwater.

Fly ash has commonly been used in concrete since the 1930s, typically replacing about 20 percent to 30 percent of traditional Portland cement. Long before that, the Romans were using volcanic ash to make concrete.

Though industry and academic researchers continue to study how to maximize the amount of fly ash in concrete, Zhang and his colleagues at Acrete believe they have hit upon a formula that creates a durable concrete made mostly of fly ash.

“That’s what makes it so different is, up to now, people have used (fly ash) as an additive to increase strength of the concrete, but this is the only solution that has 100 percent utilization of this,” Jalbout said.

The resulting product is lighter, stronger and less expensive to produce than concrete, while keeping roughly three times as much fly ash from the waste stream, Jalbout said.

The use of fly ash and related materials has been rising.

In 2015, 61.1 million tons, or about 52 percent, of fly ash and other coal-combustion products were beneficially used, up from 48 percent in 2014, according to the American Coal Ash Association.

Use of coal fly ash in concrete increased 20 percent in 2015 to 15.7 million tons – up from 13.1 million tons in 2014, the group said.

Zhang and Jalbout are working with Tech Launch Arizona, the UA’s technology commercialization arm, and UA licensing manager Bob Sleeper to bring Acrete to market.

The UA has an interest in the inventions and would be in line for future royalties from sales of Acrete, Jalbout said.

The company has filed for three international patents, including one to use the product with mine tailings — another fine particulate of particular concern in mining states like Arizona.

Acrete’s research team has had success with Acrete using different types of fly ash, including low-quality ash from China, Jalbout said.

Besides pursuing patents, Jalbout and his colleagues are working to find a manufacturer to make Acrete, as well wholesale and retail distributors.

“We’re in very advanced discussions right now,” he said, adding that he expects things to move quickly.

“Our main goal right now is to have distributors lined up and have this product ready to be manufactured or distributed by this summer,” he said.

Acrete is part of MetOxs, a Singapore-based company headed by Jalbout that is trying to advance two other UA faculty inventions involving metals.

MetOxs, which is building a new plant in Mexico, has developed a new metals-extraction process, as well as a new technology to combat metal corrosion under a subsidiary, Caltrode.

UA HEART-PATCH STARTUP

Technology for a “beating heart graft” invented at the University of Arizona College of Medicine has formed the basis for another UA tech startup, Tech Launch Arizona says.

Avery Therapeutics Inc. has licensed the heart-graft technology from the UA, and pre-clinical studies have already shown that the technology, called MyCardia, improves heart function.

The inventors, Dr. Steve Goldman, professor at the UA’s Sarver Heart Center, and Jordan Lancaster, who earned his doctorate in physiology from the UA, serve as the company’s chief medical and chief science officers, respectively. The management team also includes Jen Koevary, who earned her doctorate in biomedical engineering from the UA, as chief operating officer.