John Adkisson said he never would have guessed he could make a good beer at home when he opened his birthday present – a homebrewing starter kit − from his wife 25 years ago.

“I was barely aware you could make beer at home,” Adkisson said, “and I thought if you make it at home it can’t be very good.”

Craig Post got his start as a homebrewer in strikingly similar fashion when his wife, Kris, gave him a starter kit for Christmas five years ago.

Today, both men have advanced well beyond the starter kits, Post brewing beer in 5- to 10-gallon batches for himself, his family and friends, and Adkisson taking the giant leap into brewing beer as a business with a partner at Iron John’s Brewing Co. in Tucson.

Post sees himself as typical among the estimated 1.2 million homebrewers the American Homebrewer’s Association counted in a 2013 survey. He’s spent a little more than $2,000 on his equipment, buying the key equipment from other homebrewers who either took another step forward or just quit the hobby.

His two-car garage at his home in Forty Niner Country Club still has room for both cars, but it doubles as a brewery when he decides to cook up a batch with his or his wife’s chosen blend of grains.

“I had a friend who was selling his brewing equipment,” Post said of his purchase about a year and a half ago. “I probably wouldn’t have bought this big fancy setup but he was selling it and he offered me a decent price so I just bought what he had.”

The setup is informal but functional. Against the back wall of his garage Post has a keg refrigerator that serves as a temperature-controlled container where his beer ferments until it’s ready to be bottled and carbonated. Next to it is a metal rack of plastic containers with supplies including some of the smaller amounts of grains he uses. There are larger plastic containers stacked next to the rack with some of the more common grains he uses in larger quantities.

A rolling cart — bought from his friend — holds the equipment where the beer brewing process begins. A converted ice chest serves as the mash tun where the grains go through the first process on the way to becoming craft beer. A beer keg connected to a system of tubing sits on the bottom rack of the cart holding 10 gallons of hot water needed in the process.

The cart can be wheeled around the garage as needed and is easily stored to the side during idle times so Post can keep the family car out of the hot sun during the Tucson summers.

A standard burner for a 10-gallon boiling pot is also part of the equipment and also is easy to move around the garage.

“Typically you’ll see someone set up in a corner of their garage or have a small part of a closet devoted to their equipment,” said Gabriel Gudenkauf, an assistant manager at Brew Your Own Brew, one of the primary suppliers of home brewing equipment and ingredients in Tucson. “I guess it depends on how in-depth someone wants to go with it.”

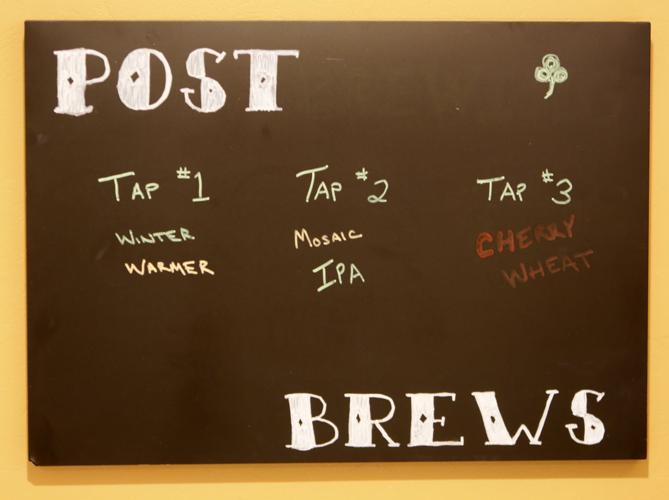

Inside Post’s home, he has a keg refrigerator where he keeps three different varieties of beer on tap from 5-gallon kegs normally used to dispense sodas. An indoor storage room has other supplies that don’t have to be as readily accessible, including spare kegs.

With more than $2,000 into the equipment, Post, who makes a living as a software developer, said the economics of his purchases were a no-brainer. On top of that, the additional equipment allowed him to delve into making a wider variety of beer because the extracts a brewer purchases for use with the starter kits limit the grains — and consequently the flavors — available.

“Most of the stuff that I’ve bought is to make it cheaper,” he said. “With the extract it’s really hard to make your type of beer. There are only certain types of beer you can make, and it’s also very expensive. It’s essentially 60 bucks for two cases.”

By comparison, an equal amount of the batch Post was brewing last week will cost him about $18 per case in supplies.

But it’s not just about the cost, he said.

“It’s always a choice of higher quality,” he said. “You always want to make better stuff.”

Which he said he did right from the start when he bought the equipment from his friend.

“It was good,” he said of his first batch of beer with the expanded setup. “I think it was my best hefeweizen (German wheat beer) I ever made and I haven’t been able to duplicate it. That’s the way it goes.”

From similar beginnings, Adkisson went from a starter kit to a 500-square-foot spread in his backyard, where he became an award-winning homebrewer and ultimately co-owner of a small brewery that opened in 2014.

“It appealed to me to create something,” he said of his first venture into homebrewing. “I like beer and I got an idea into my head to make an oatmeal stout. I made something I really liked and tried a few different things. Then I entered it into a local homebrew competition and got a blue ribbon.”

Adkisson had caught the homebrewing bug and gave up his accounting job to work as brewing assistant at a local brewery. But the business closed and he went back to accounting and homebrewing. He continued to take brewing seriously and became a certified beer judge while also winning national awards as a brewer.

He continued to expand his setup, committing an outdoor storage unit to his equipment. He put it next to a covered patio where he installed sinks and laid down brick so he could roll his equipment around as needed. He bought refrigerators and installed storage racks.

It all was to make sure he had a supply of beer on hand while batches were in process.

“It grew from a need to have bigger batches and not run out of beer,” Adkisson said. “When you make a 5-gallon batch of beer, you have to wait a month before you drink it. I realized I had to have beer to drink while other batches were brewing.

“Then I started entering competitions. I had events and parties for family and friends. I kept stepping up from 5 to 10 to 20 gallons.”

Adkisson was a founding member of the Tucson Homebrew Club formed in 1995 to bring brewers together monthly to share ideas, recipes, techniques and other information related to their craft. It was a relatively small society at the time that has now become a growing national passion.

“The first 15 years I was brewing, everybody knew everybody else and then it kept expanding in wider circles,” Adkisson said. “You would find some people who would brew a couple times and stop and say, ‘That was fun.’ Others brew anywhere from three to six times a year.

“Then there are knuckleheads like me who invest thousands of dollars and thousands of hours in pursuit of the perfect batch of beer. ... It’s not about the fact that I can’t find something similar; it’s the fact that I made this and controlled all elements and it came together.”