Tucson-area optics firm Geost has been supplying sensor systems for U.S. defense and intelligence satellites since its founding by a University of Arizona optics Ph.D. two decades ago.

Now, Geost is rapidly expanding its headquarters and lab spaces in Marana to help the nation shift to networks of smaller satellites, with the backing of a private-equity firm that acquired most of the company in 2021.

The company, now part of LightRidge Solutions, recently cut the ribbon on an expansion that doubled the production capacity at its main facility on West River Road, near Orange Grove Road, with plans to double that again later this year.

Over the past three years, Geost has boosted its employee count by 600% to more than 200 workers now after hiring more than 95 over the past year alone, with plans to add 100 more workers this year.

“Geost has been around for 20 years, doing pretty much the same thing but expanding in the national security space around providing optical sensors and payloads,” said Rich Gray, who was named president and general manager of Geost in 2022 after a 26-year career at General Dynamics in Scottsdale.

Geost needs the new hires to handle an influx of new business and continuing contracts.

The company specializes in the design and production of electro-optical and infrared sensors and integrated sensor packages, or payloads, that fit onto satellites to detect and track objects and activity in space, as well as ground-based sensors.

Tracking missiles

Last week, Geost announced a contract from Colorado-based Sierra Space to provide sensor payloads for the U.S. Space Development Agency’s Tracking Layer Tranche 2 missile warning and tracking satellites.

Geost will provide 16 of its Mercury missile-warning and missile-tracking payloads and two of its Phoenix fire-control payloads for missile defense, including integrated mission processing systems.

Last September, Geost announced it is building sensor payloads for eight Northrop Grumman-built missile-warning satellites, along with related ground-based systems, for the SDA’s Tranche 1 Tracking Layer satellites projected to launch in 2025, under a $617 million contract awarded to Northrop in 2022.

The company says its Starlite “resiliency” payloads are significantly smaller and more affordable than previous payloads, at about the size of soda can.

“Geost’s resiliency payloads provide warning of threats or potential threats to orbiting assets, enabling them to take defensive or other actions as needed to protect themselves,” Gray said.

Geost makes sensors for “space domain awareness” — essentially giving satellite operators a picture of what is going on around them, including other satellites, space junk and sources of interference, for example.

Founded in 2004 by UA optics Ph.D. Anthony Gleckler, Geost has quietly developed and produced electro-optical sensor systems for the Air Force, and more recently the Space Force, since its inception.

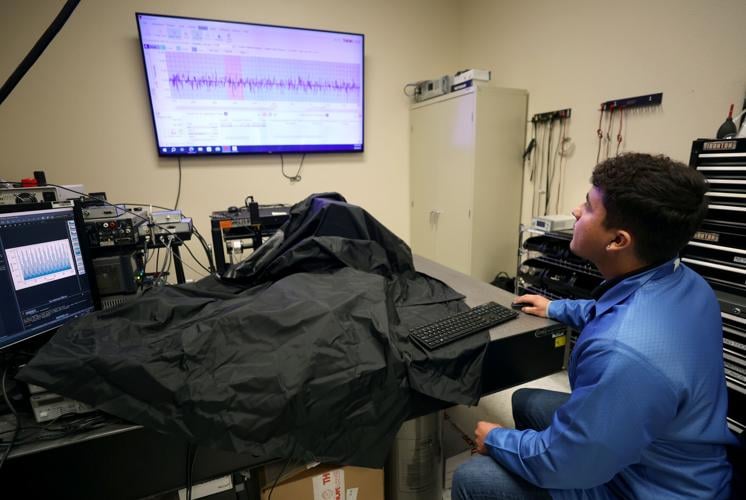

Scientist Dymetris Ramirez tests a piece of equipment at Geost.

‘Sweet spot’ in space

A majority stake in Geost was acquired in 2021 by the private-equity firm ATL Partners. Geost is now part of LightRidge Solutions, formed by ATL with two other ATL acquisitions in the same sector, Colorado-based laser-radar sensor maker Ophir Corp. and Virginia-based space electronics provider Trident Systems.

Gleckler remains a consultant to the company and board member.

Gray said the company has found its “sweet spot” as the Pentagon and U.S. intelligence agencies move away from systems using relatively few, large satellites to networks of much smaller and cheaper satellites.

Gray

With satellites now relied on for military communications, command and control of air- and ground-based platforms and weapon systems and missile tracking and warning, the Pentagon is seeking to create networks of smaller sats to provide redundancy in the face of emerging space threats.

Geost’s sensor payloads, which range in size from a soda can to a breadbox, generally cost less that $10 million each, and often much less, Gray said, while providing critical resilience to the U.S. satellite fleet.

“What we’ve seen over the past few years is a trend towards more affordable, more proliferated architectures, getting away from having the the big targets, the highly capable, school-bus sized assets, to more disaggregated constellations,” he said, “where if an adversary were to try to take out some of the capability, there would be plenty of other assets to fill in, which makes it obviously harder for an adversary to gain an advantage.”

“So we’ve kind of hit a sweet spot in terms of the size, weight and performance of our systems, and the cost,” Gray said.

Besides space-based sensors, Geost also designs and makes ground-based sensor stations that see into space for applications such as laser-based data transmission, which the company is testing at sites including the UA Tech Park on Tucson’s south side.

The company develops its own payload software, which uses artificial intelligence and machine learning autonomous technologies to process critical data.

The company reached a milestone last year when one of four payloads delivered to an undisclosed customer was sent into orbit and became operational, Gray said.

Geost now has three programs moving into operations and maintenance, five programs moving into production and seven programs in the research and development phase, including one commercial project.

Growing presence

With much work ahead, Gray said the company isn’t done expanding its main office and labs, which are tucked away in a retail and office center just east of Interstate 10.

The company spent nearly $1 million on the most recent expansion including new three new optical labs and a third clean room, a 1,000-square-foot, Class 7 facility, for contaminant-free assembly and testing.

With plenty of space for further expansion in the former furniture store building, Gray said, the company plans to add another clean room and two more production lines by the end of this year or early 2025.

The company, which still has an engineering office further east near River Road and La Cholla Boulevard, also is in the process of setting up an office with labs in Northern Virginia to handle operations and maintenance for its “on-orbit” missions, Gray said.

Geost has tapped into talent from the UA and the local optics industry.

Many of the company’s engineers formerly worked at Raytheon in Tucson, including David Dean, director of integration and production, who joined Geost last year after more than 17 years as an electrical engineer at Raytheon.

Raytheon, part of RTX Corp. after a merger with United Technologies in 2021, has made satellite systems for decades, and its Tucson missile operations include labs to make space sensors for ballistic missile interceptors.

And Raytheon recently got into the small-sat sensor business with its acquisition of Colorado-based satellite maker Blue Canyon Technologies in 2020 and satellite electronics provider Seakr Engineering in 2021.

In February 2023, Raytheon was awarded a $250 million contract to provide seven missile-tracking satellites for the SDA’s Tranche 1 Tracking Layer.

Reaching capacity

During a tour of Geost’s expanded facility on West River Road, several windowless optics labs allow engineers to test components using lasers and other equipment.

In the company’s newest clean room, Dean and company engineers were setting up a robotic arm to make precision measurements of satellite payload components.

They also showed off a computer program in final development to track each project at each point of progress in real-time — important while the company juggles multiple contracts, Dean said.

But an old-fashioned project-tracking whiteboard with color-coded project magnets will stay, to help engineers quickly spot work bottlenecks as soon as they come in for their shifts, he said.

“When we finish the build out this year, we will be pretty much at capacity and we’ll be able to support all the work that we have,” Gray said. “We’re committed to staying in the Tucson area, and growing in the Tucson area.”