The Clifton-Morenci mining district in eastern Arizona is sometimes referred to as the Copper Mountain mining district. But while known mainly for copper deposits, it also produced uncommon minerals.

These include covellite, a dark indigo-blue iridescent secondary mineral associated with chalcocite and found as a coating on pyrite in sericitized porphyry. Dioptase, a secondary copper silicate, is also found in the district, where it is associated with chrysocolla in limestone. Coronadite, a lead manganese oxide, was first discovered in the Coronado vein.

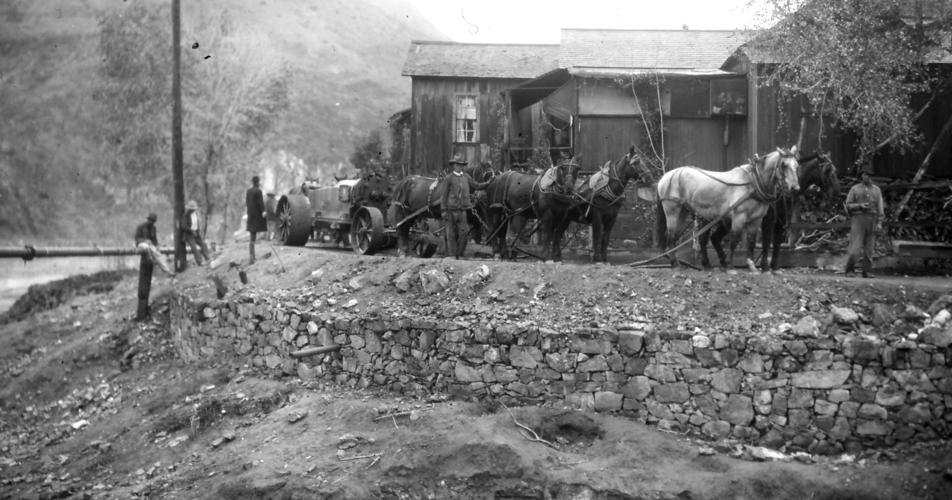

While the copper deposits in the Morenci region contain little gold, the reverse is true in the outlying areas. The gravels along the San Francisco River 4 miles north of Clifton sparked the interest of the Clifton Hydraulic Co. in the early 1880s, which invested in 4 miles of iron pipes to channel water to exploit gold found in the placers.

Excavations from surface to bedrock were also undertaken between 10 to 30 feet over a 3,000-acre area. Gold-bearing quartz veins above the placer deposits were also worked, producing $20 of gold per ton. Gold-bearing veins embedded in diorite-porphyry rocks found in Gold Gulch west of Morenci have been intermittent producers.

The Lakemen Mine, comprised of underground workings that included a 300-foot vertical shaft, multiple levels and over 400 feet of drifts, was the most notable producer between 1885 and 1895.

It is said that the renowned Western artist Frederick Remington spent a year placering around Gold Gulch. He discovered $6,000 worth of gold in three weeks by removing a mass of boulders that revealed a depression wherein gold-rich gravels had settled.

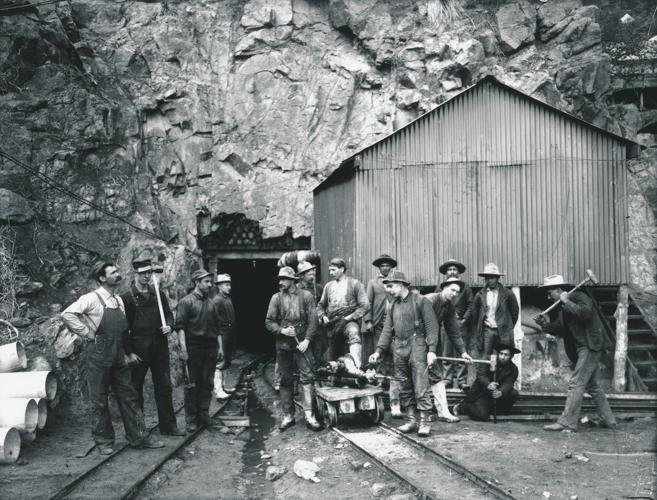

Metcalf served as the company town for the Arizona Copper Co. The town, along with the company’s primary mines the Coronado, Metcalf and the King, were located among the mountains overlooking Chase Creek.

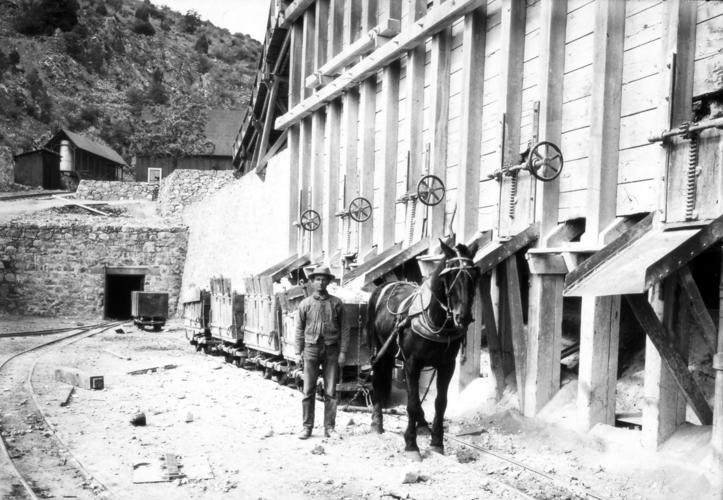

Acquired by the Arizona Copper Co. in 1883, the town was already transporting ore from the Coronado Mine by the baby gauge Coronado Railroad. The area was well known for its steep inclines, including the Metcalf incline which descended 500 feet. At the base of the inclines were five ore bins adjacent to the Coronado Railroad for ease of transport. Ore was shipped to the Clifton smelter for refinement.

Rising copper prices from 10 cents to 17 cents per pound in 1887 enabled the reopening of the Coronado Mine. Market copper prices were directly influenced by attempts through orchestrated purchase contracts with copper producers by the French syndicate under M. Secretan to corner the world copper market.

Rail transport continued to improve and by 1884 a narrow-gauge railroad was completed connecting Clifton 4 miles southeast of Morenci to the Southern Pacific Railroad at Lordsburg, N.M., 59 miles further south.

Guthrie along the Gila River served as a transfer station for freight and ore shipments comprising copper carbonates (azurite and malachite). Established by the Arizona Copper Co., the town was christened after John Guthrie Smith, a Scottish stockholder.

With leaner ores prevalent during the 1890s, treatment necessitated the need to erect more on-site concentrators.

The Detroit Copper Co. successfully operated Arizona’s first copper concentrating plant beginning in 1886, processing oxide ore containing 6.5% copper, concentrating it up to 23.8% copper and leaving 3.9% copper in the tailings. It produced up to 5 million pounds of copper a year until 1892, when it was forced to close due to declining copper prices of 10 cents per pound.

Lack of capital necessitated it be sold to Phelps Dodge and Co. by 1897, including the Arizona Central, Copper Mountain, Manganese Blue, Montezuma and Ryerson mines. The added capital from Phelps Dodge heightened production from these mining properties from 7 million pounds of copper upon acquisition to 29 million pounds in 1908.

By the turn of the century, diminishing carbonate-oxide ores necessitated the need for heightened exploration and production of low-grade sulfides in porphyry.

The Arizona Copper Co. rose to this challenge, erecting the 5,000-ton No. 6 concentrator in 1906 to treat the 3% ore (mainly chalcocite) from its primary producing property, the Humboldt Mine. It produced up to 4,500 tons of ore per day.