Logistical challenges of transporting ore for refinement and market have proved challenging throughout Arizona’s mining history.

Perhaps one of the biggest challenges was found in the White Mesa mining district in Navajo Country, which was discovered to contain disseminated copper mineralization in the 1870s.

The area known today as Copper Mine or by the Navajo name “Beesh Haageed,” meaning “Digging out Metal,” is one of the few copper mines found in Northern Arizona.

The mineralization is apparent, ranging from pale blue, blue to green copper ore samples. These are impregnations by copper carbonates and silicates of Navajo sandstone matrix including malachite and chrysocolla. Some azurite and cuprite was also recovered onsite.

The Copper World Mine and nearby Little Dick Mine are considered the most mineralized mining properties in the district.

Early ore samples from a 600-foot-wide, gray sandstone outcrop traced over 10 square miles of copper-bearing ore varying up to 15%.

Later drill sampling revealed about 600,000 tons of measurable ore with up to 14 million aggregate tons existing in blind ore bodies below the surface in outlying areas.

Inadequate water supply coupled with lack of nearby smelting facilities necessitated cost-effective transportation measures in the beginning of development.

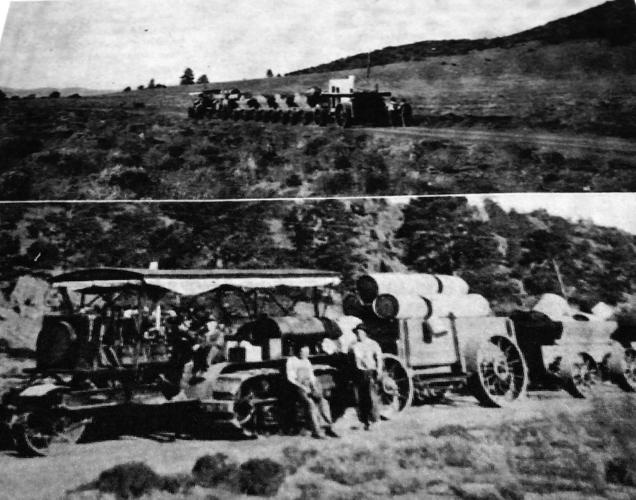

The Navajo Copper Co. was one of the earliest mining companies to operate gasoline-powered tractors for ore transport.

Before that, early experience in the 1900s with ox teams hauling ore proved costly. Later, motor trucks were employed over the sandy terrain, but yet again, excessive transport costs over $100 per ton hindered the profit margin.

Holt Manufacturing Co. engineers were called in to survey the site, providing beta testing with several Caterpillar tractors. Mine officials were impressed and requested 14 Caterpillar tractors and two from another manufacturer. The employment of Caterpillar No. 75 tractors reduced costs and improved efficiency.

Working in pairs, each tractor hauled wagon trains laden with ore. These tractors were made by Holt in Stockton, California, which claimed each could do the work of 38 horses.

An orderly haulage system was set up, transporting up to 1,500 tons of ore per month over a 97-mile distance comprised of mountains, high desert and drifting sands.

The distance was broken down into three relays from the Little Dick and Copper World claims to the Gap (24 miles), the Gap to the bridge crossing over the Little Colorado River (35 miles), and from the bridge to camp No. 1 also known as Copper Camp (38 miles). That camp was operated by the Arizona Lumber and Timber Co., several miles north of Flagstaff.

It was there that the ore was shipped by the Atchison, Topeka and Santa Fe Railway to smelters in the Southwest. Daily and nightly shifts employed relief drivers at given relay points along the way, ensuring the constant movement of ore and supplies from the mine to rail head and back to mine for the next shipment.

Because of the amount of drifting sand from the mines to the Gap, tractors needed 24-inch tracks. In the rest of the journey, 20-inch tracks proved suitable for tractors. Total cost for tractor haulage was $11.40 per ton.

Operations were directed by Ernest Metcalf and Percy M. Ferber, who served as president and secretary-treasurer of the Navajo Copper Co. The company’s vested interest proved brief, after several years of development and 1,077 tons of ore shipped for processing.

Intermittent mining efforts in later years by the Coconino Copper and Chemical Co., the Mardun Co. and the Shattuck-Denn Mining Corp. continued into the 1960s. The irregular distribution and small nature of the ore bodies led to eventual abandonment of the enterprise.

The Copper Mine Trading Post and Café remains structurally intact at present, though abandoned, with an eminent roof collapse and exposed insulation. The rock café was built in part with copper ore inlay, including the interior fireplace.

The large open cut seen just south of the Copper Mine Trading Post and west of Navajo Route 20 includes the Gopher, Copper World and Ida M. Smith Mines.

It appears to be undergoing some type of reclamation, as metal stakes backing straw wattles as erosion barriers are prevalent across the open cut.

These remnants bear testimony to some of the most remote copper mining localities in Arizona.