Like many copper mining towns in Arizona, Ray was booming in its heyday.

Ray — about 90 miles north of Tucson and 80 miles east of Phoenix — was the largest town in Pinal County in 1914, with a population of 5,000.

Located at the foothills of the Dripping Spring Mountains on Mineral Creek, it had a newspaper, the Copper Camp, and was the headquarters for the Valley Bank and Miners-Merchants Bank.

It also included many amenities such as the 12-room Ray Hotel, the Iris — a movie theater that subscribed to the movies of the day including those starring Tom Mix and Charlie Chaplin — and the Miller Bros. grocery and department stores.

Mining around Ray all began with a loose organization of silver prospectors in 1873.

But it soon developed into a more substantial mining operation with the erection of a five-stamp mill in 1880 by the Mineral Creek Mining Co. An English company, Ray Copper Mines Ltd., later failed in its attempt to exploit the ore at the site at the turn of the century because of inadequate sampling, leading to unrealistic expectations of higher-grade ore of 4 percent.

It was not until Daniel C. Jackling’s successful exploitation of the low-grade porphyry ore at Bingham, Utah, that similar potential was seen at the Ray Mine. With Jackling’s financial support, his associates Philip Wiseman and Seeley Mudd obtained options at Ray beginning in 1907.

Soon afterward, the merger of the Ray Copper Co. and the Gila Copper Co. formed the Ray Consolidated Copper Co. or Ray Con, which would later absorb the Arizona Hercules Copper Mining Co., Kelvin Calumet Mining Co. and Ray Central Mining Co.

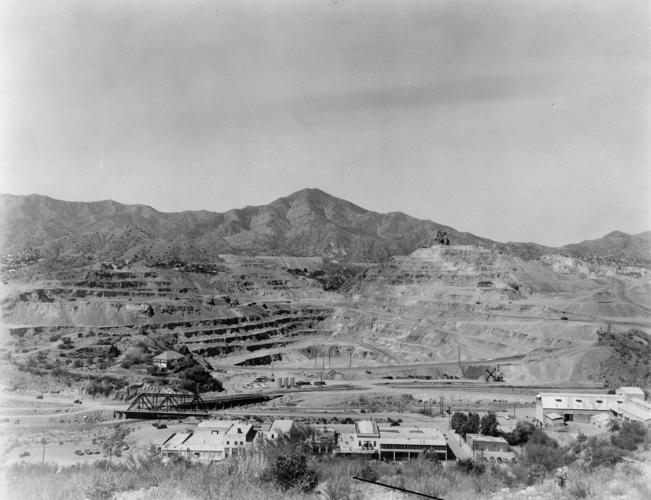

In 1909, mining operations comprised 1,000 acres of lode claims around the town of Ray in the Mineral Creek Mining District. This prime land, part of a mineralized belt of highly altered and silicified schist running two miles east and west and one mile width north and south, enticed extensive development. More than 350 churn-drill holes were put down over 400 feet in depth. Of these, 277 holes indicated commercial ore averaging 2.17 percent copper below 250 feet of overburden, revealing an ore deposit consisting of disseminated chalcocite.

The churn-drilling program determined the potential of how much low grade ore could be mined in a large scale. The operation was overseen by Louis S. Cates, who initiated successful block caving methods that yielded over 8,000 tons of ore per day.

A mill was built at the juncture of the Gila and San Pedro rivers, producing copper beginning in 1911. Ore transport was by the standard gauge Ray and Gila Valley Railroad, a subsidiary of Ray Con. Built in 1909-’10, the railway from Ray connected eight miles to Ray Junction, the access point along the Arizona Eastern Railroad, which in turn transported it to the mill 18 miles away.

ASARCO built a smelter at Hayden in 1912 and contracted with Ray Con to smelt its concentrates, shipping the blister copper to its refinery at Perth Amboy, New Jersey.

With copper at 16 cents per pound in 1912, the company made a profit with dividends finally being made by June 1913. At the time, around 30 miles of underground exploratory work had been undertaken with 80 million tons of ore developed. More than $10 million had been invested in erection of the mill, railroad and equipment.

Advances in technology further made the deposit attractive despite lowering grade levels of ore. The use of a new flotation reagent made processing ore gravity concentration obsolete.

In 1917, Ray Con produced 44,500 tons of copper, ranking as Arizona’s second-largest copper producer. A 1918 panoramic image of Ray showed lines marked in the hillsides caused by caving ground resulting from the removal of underground ore. A distant building with four smokestacks contained an air compressor providing ventilation underground and compressed air for mining locomotives.

Ray Con was acquired by the Nevada Consolidated Copper Co. in 1926. Kennecott Corp. assumed control of its holdings by 1933 and direct control of the company within the next decade, forming the Ray Mines Division, Kennecott Copper Corp.

The block caving system developed by Cates saw drawbacks at Ray because of an area of tough rock that failed to fragment properly, along with mill extraction challenges based upon the mixture of sulphide and oxide ore.

By 1955, underground mining would be superseded by open-pit mining resulting from larger earthmoving equipment designed to transport greater amounts of ore, replacing railroad and hand laborers at the mine site while forever changing the surrounding landscape.