San Manuel Mine was once the world’s largest underground copper mining operation in size of ore body, production capacity and infrastructure.

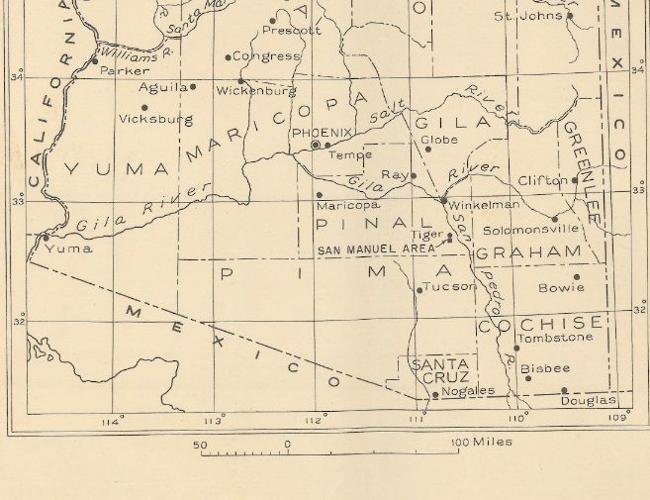

It is located in the Old Hat mining district on the east side of the Black Hills, a northerly continuation of the Santa Catalina Mountains.

Prospectors in the 19th century were drawn to a prominent hill of monzonite stained with red iron oxide. They made minor discoveries, with early gold production of around $3 million at the Mammoth and Mohawk mines (Tiger), one mile north of the San Manuel ore body.

Low-grade oxide mineralization on the lower San Pedro River Basin discovered during World War One proved unprofitable.

Geology of the San Manuel disseminated copper deposit embodies quartz monzonite, diabase and monzonite porphyry. Regional compression over 100 million years ago was responsible for the fracture of the rocks, along with the injection of hydrothermal solutions of varied composition. This produced primary ore deposits containing chalcopyrite and molybdenite.

Few investors would have had the million dollar capital to exploit the elliptical shaped ore body beneath an average 670 feet of overburden comprised of Gila conglomerate and weakly mineralized monzonite. The sulfide ore, mainly chalcopyrite, ranges in depth from 500 to 2,700 feet, averaging 0.785% copper content. The upper part of the ore body is in the oxidized zone, mainly coatings and stringers of blue chrysocolla and also red colored cuprite averaging 0.717% copper content.

Later owners James M. Douglas, Burns Griffin, Victor Erickson and Henry W. Nichols applied for a $94 million development loan from the Reconstruction Finance Corporation in 1943. Nichols, an assayer for the Magma Copper Co., christened the claim San Manuel.

Positive results from churn drilling conducted by the U.S. Bureau of Mines enticed the Magma Copper Co. to acquire the property in 1944.

One-hundred-and-nine holes totaling 205,536 feet were drilled, revealing an outline of a large tonnage of low-grade disseminated copper sulfide mineralization.

By 1955, two 2,950-foot production shafts penetrated the San Manuel ore body. Production began in 1956 with the activation of the mill and “blown in” smelter.

Relying on water from the San Pedro aquifer, the company town of San Manuel, 7 miles southeast of the mine site, was built in the early 1950s.

It would reach a population of 5,000 with 1,200 Del E. Webb and M.O.W. homes built along with the concentrator, smelter and administration building.

Mining properties comprised 12,000 acres of patented land with the recovery of copper and molybdenum.

Factors that prohibited initial open pit mining included the thickness of the overburden and the size and shape of the ore body. Block caving was the primary means for ore extraction in the underground sulfide ore body.

It necessitates the undercutting of large blocks of ore, after which stresses caused by the undercutting cause the ore to crush and fracture. Gravity induces the ore to fall through the grizzlies consisting of rails spaced 14 inches apart.

The large pieces of ore are reduced in size to less than six inches by a sledge hammer. The ore continues through vertical or inclined shafts into ore cars at the haulage level.

The underground electric railroad system moved the ore to dump pockets, after which 5-ton skips transferred it to the surface and deposited it into ore storage bins prior to shipment for crushing, smelting and refining at San Manuel.

A 1,600 horsepower, 125-ton diesel electric locomotive transported 100-ton capacity bottom dump railroad cars laden with ore 7 miles on standard gauge to the mill.

Underground mining operations involved four production shafts and three service shafts from 700 to 4,000 feet below the surface.

Production shafts were used to move ore and send exhaust to the surface.

The service shafts transported miners to the workings, along with providing intake ventilation and supplies.

The ventilation system circulated 1.3 million cubic feet per minute of forced ventilation air to the underground workings.

Edward Thomas, employed as a ventilation engineer for Magma, worked the 3,740-foot level of the mine wherein the temperature was 112 degrees. Miners working at that level would need to wear ice vests. Thomas was charged with restarting three spot coolers, also known as reefer units (50-ton air chillers), and ventilation fans in order to keep working temperatures at 85 degrees.

Several commercial freight rail lines included the San Manuel Arizona Co. short-line connecting Southern Pacific at Hayden and the Magma Arizona Railroad Co. connecting Superior and Florence Junction.

Expansion for Magma occurred in 1968, with the purchase of the Kalamazoo ore body from Quintana Minerals doubling Magma’s reserve size.

Development of the Kalamazoo ore body, a faulted segment of the San Manuel deposit one mile west of the San Manuel, began in 1990 and continued through 1999.

During the 1970s, San Manuel would erect a second smelter stack and initiate recovery of sulfur dioxide emissions from the smelter converting over to sulfuric acid. An electrolytic refinery and rod casting plant would also be installed along with the installation of air quality control systems.

Beginning in 1978, Magma began mining an average of 50,000 tons of rock from the nearby Tiger Mine as smelter flux.

Broken Hill Proprietary Co. Ltd. merged with Magma in 1996, acquiring the property.

Declining copper prices necessitated a halt in production and ultimate closure of the San Manuel mine site by 2003. Plant facilities and the smelter stacks were demolished in 2007.

From 2013 to 2016, San Manuel hosted a Transload Facility operated by the San Manuel Arizona Railroad Co. (SMARRCO) for concentrates shipped from the Pinto Valley open pit mine 6 miles west of Miami.

The majority of concentrates from Pinto Valley were trucked to San Manuel, stored, then loaded onto 100-ton railcars to the Port of Guaymas, Sonora, and then shipped to China. Economics and efficiency necessitated replacement by modular truck transport.

The operational life at the San Manuel-Kalamazoo Mine produced 703,686,000 short tons of sulfide ore and 92,969,000 short tons of oxide ore. Total production of copper and molybdenum was 4,651,600 short tons and 73,200 short tons.