A Utah-based advanced battery startup is looking to break ground in October on a factory in Tucson, after announcing a major round of funding from development partners.

American Battery Factory Inc., plans to initially hire about 300 workers and may eventually employ up to 1,000 to make lithium-iron phosphate battery cells. It has raised “significant development capital” to build out its first plant south of the airport, the company announced Monday.

The investment round was led by Utah-based Lion Energy, a maker of portable battery packs and energy-storage systems and an initial investor that helped launch the battery startup in 2021.

Other investors in the fundraising round include hybrid manufacturing partner FNA Group, a Wisconsin-based maker of electric and gas pressure washers and related equipment, as well as an unnamed battery-cell equipment manufacturing company.

The amount of funds raised was not disclosed by the privately held companies.

American Battery Factory plans to produce lithium-iron-phosphate battery cells for home and commercial energy-storage systems at Pima County’s Aerospace Research Campus.

ABF has already developed a line of lithium iron phosphate battery cells (also known as lithium ferro- phosphate or LFP), which it says are less environmentally hazardous and safer than common lithium batteries using cobalt and nickel while providing higher power density and lower weight.

The new funding will allow ABF to secure production equipment and security technology needed for the first development phase of its planned Tucson plant, said Jim Ge, CEO of American Battery Factory.

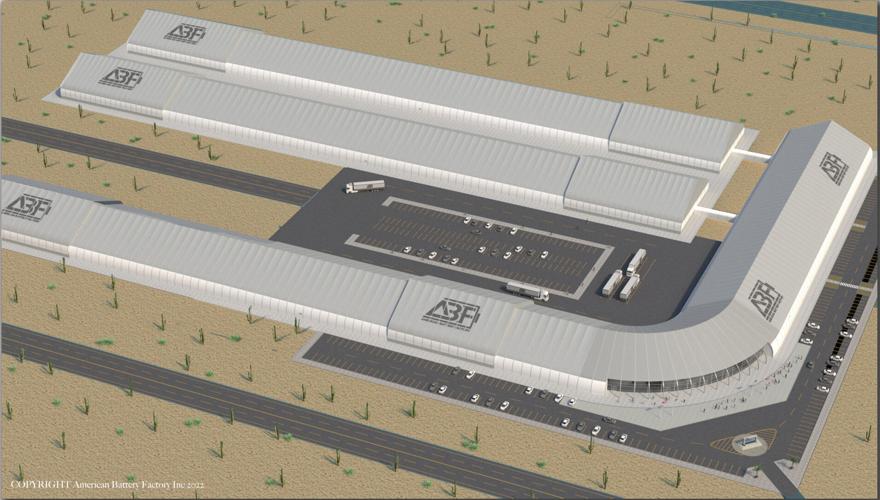

The company announced in December the first of a planned network of U.S. battery “gigafactories” using modular, “tension fabric” buildings.

The so-called Series A investment round was limited to development partners, but the company plans to complete a Series B round with institutional investors later this year, Ge said.

“Our vision is to help the United States rapidly electrify, and energy storage is the only solution that makes this possible,” said Ge, who is also co-founder and chairman of Lion Energy. “The first major step on this journey will be the construction in Arizona of the largest U.S. gigafactory for producing LFP battery cells, with initial development funded by this Series A round.”

The company is completing soil testing at the local site in advance of groundbreaking, and construction of ABF’s initial factory will take about a year, Ge said.

The company, which plans to invest some $1 billion in its local facilities over time, is working with Sprung Instant Structures, a longtime Canadian maker of tension-fabric buildings that has supplied companies including SpaceX and Tesla with quick-start factory sites and has thousands of its structures in use worldwide.

ABF plans to start with an annual cell production capacity of 3 gigawatt-hours (10,000 kWh) and scale up to 16 gWh, Ge said.

“We anticipate delivering our first battery cells within the next 18 months,” he said.

The company plans to erect modular “tension fabric” structures to build out its highly automted factory in phases, starting with a 2,000-foot long, 400,000-square foot initial building.

Jim Ge, CEO of American Battery Factory Inc.

The Pima County Board of Supervisors in December approved a conditional lease-purchase agreement with American Battery Factory for up to 267 acres of land in the county’s Aerospace Research Campus south of Tucson International Airport.

American Battery Factory was founded as Lion Energy looked to “reshore” from China to the U.S. manufacturing of the battery cells that go into its line of portable power packs, solar generators and grid-level energy storage systems.

ABF’s lithium iron phosphate battery chemistry is ideal for such applications, and Lion Energy has signed an offtake agreement to buy 18 gigawatt-hours worth of LFP battery cells.

FNA also is focused on reshoring its supply chain as it plans to offer new, battery-powered power washing equipment, its chief executive said.

American Battery Factory plans to eventually employ up to 1,000 people at its ‘gigafactory’ near the Tucson airport.

Founded in 1988, FNA Group is a market leader in pressure washers and one of the most vertically integrated power equipment manufacturers in the industry with a global presence across the U.S., China, Italy and Australia.

The company recently announced the move of critical component manufacturing to North America to help innovate new and more efficient products.

“Our focus as a company is to bring our entire supply chain to North America and this is now possible through American Battery Factory,” said Gus Alexander, CEO of FNA Group. “Our global plan is to electrify all our next generation of products by utilizing ABF battery cells. We are proud to support the company in this round of funding to ensure a domestic supply chain for all.”

Those goals align with U.S. policy aiming to reshore manufacturing jobs and drive clean-energy investment to battle climate change.

To spur domestic energy-storage manufacturing, the Inflation Reduction Act of 2022 offers tax breaks of $35 per kilowatt hour of battery cell production and $10 per kWh for battery module production.

ABF should qualify for the cell production incentive, while Lion should qualify for the module incentive as it assembles battery packs for its products, Ge said.

“Even before the IRA law passed, we did our numbers, we did our studies,” he said. “The USA can be very competitive compared to China already. These IRA tax benefits are more helpful.”

Meanwhile, Ge said the company is working with Pima Community College and the University of Arizona to develop a talent pipeline for ABF.

Pima recently completed construction of its $35 million Advanced Manufacturing Building as part of a major expansion of its Center of Excellence in Applied Technology at the Downtown Campus.

The facility, expected to open for classes this fall, includes labs for advanced skills including robotics, and a flexible industry training lab where employers can send workers to get specialized training on specific equipment.